Casters, the unassuming wheels affixed to the legs and bases of everyday items, are often overlooked. Yet these miniature marvels play a significant role in enhancing the movement of equipment and furniture across numerous environments. For facilities managers, business owners, and homeowners alike, selecting the right caster can dramatically reduce effort and enhance workflow. From heavy duty wheels in warehouses to smooth-gliding units in hospitals, the influence of casters extends well beyond industrial settings, affecting everyone’s comfort and productivity.

Incorporating casters into office and healthcare settings enhances mobility and efficiency by allowing for the easy movement of chairs, cabinets, and critical equipment. These adaptations not only promote productivity by reducing physical strain but also cater to specific needs, such as quiet operation in hospitals or secure lockable designs. As technology advances, modern casters have become increasingly specialized and ergonomic, underscoring their importance in ensuring safety and optimal performance in diverse environments.

Types of Casters and Their Applications

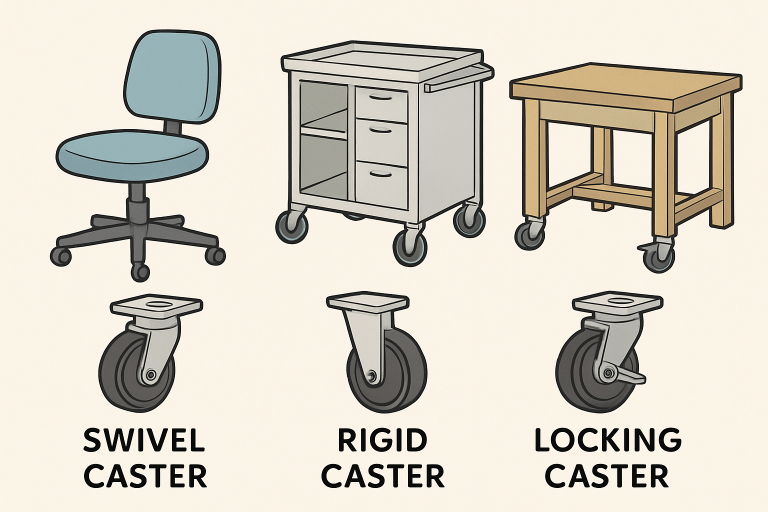

Every application has unique performance and handling requirements, so understanding the differences between caster types is essential. The three primary types include:

- Swivel Casters: These allow for 360-degree rotation, offering maximum maneuverability. They are ideal for applications where frequent changes in direction are necessary, such as on office chairs, service carts, and medical trolleys.

- Rigid Casters: Fixed in orientation, rigid casters only move back and forth, making them well-suited for tasks that require consistency in direction, such as transporting heavy machinery or industrial carts along straight pathways.

- Locking Casters: Equipped with mechanical brakes or locks, these casters provide stability when stationary, minimizing movement for equipment such as workbenches, hospital beds, and rolling displays.

Choosing the appropriate caster type is determined by the object’s function, expected load, surface, and frequency of movement.

Advancements in Caster Technology

Modern caster technology has significantly enhanced the user experience through engineering that prioritizes comfort, safety, and equipment longevity. Shock-absorbing casters, for example, use specially designed cores or elastic tires to reduce vibration when traveling over rough surfaces, protecting both cargo and operators. Innovations in noise-reducing materials and ball bearing design are a quiet improvement—a critical benefit in hospitals, libraries, and offices where silence is valued.

Ergonomic improvements, such as integrated tread design and lightweight materials, have made pushing and pulling loads easier, significantly lowering the risk of injuries associated with material handling. Many hospitals and manufacturing facilities now require casters with enhanced mobility and less push force as part of their safety and labor-saving protocols. Industry experts discuss how innovations in caster design continue to deliver safety and productivity benefits, as featured in platforms like Safety+Health Magazine. These advancements also help organizations extend the lifespan of their equipment by reducing wear and tear. As more industries prioritize efficiency and worker well-being, demand for high-performance caster solutions continues to grow.

Ergonomics and Safety Benefits

The ergonomic benefits of casters directly translate to lower injury rates and higher employee satisfaction. Casters reduce the need for manual lifting and awkward stretching, mitigating the risk of musculoskeletal strains or repetitive-use injuries. Ergonomically engineered casters are now often required in high-traffic environments to support operators who must move substantial loads.

Safety is another primary concern that has driven recent innovations in casters. Anti-slip wheel materials, intuitive locking systems, and reinforced housings have become standard in many workplaces, making sure that moving heavy objects is safer and more stable than before.

Industry-Specific Uses of Casters

- Healthcare: Silent rolling and resistance to debris or fluids are crucial for hospital beds, IV stands, and surgical carts. Casters help doctors and nurses provide focused patient care, with less energy wasted on moving equipment.

- Manufacturing: Heavy-duty casters streamline workflows, enabling the easy maneuvering of large machinery and bulky loads. Specialized casters help factories increase throughput and lower the risk of workplace accidents.

- Retail: In stores, swivel casters make it easy for shopping carts and portable displays to navigate narrow aisles and respond to rapid layout changes.

Choosing the Right Caster for Your Needs

Several crucial factors help determine which caster will perform best for a given scenario. Load capacity is foundational: exceeding recommended limits accelerates wear and can cause accidents. Floor surface matters too—rugged wheels are generally best for carpeted areas, while softer treads excel on concrete or tile.

Environmental considerations also influence the choice; casters exposed to moisture, chemicals, or aggressive cleaning protocols should use corrosion-resistant materials. Specialized needs, such as shock absorption or noise minimization, may drive a preference for advanced designs. Always review manufacturer guidelines and consider consulting with professionals to ensure the best match for your needs.

Maintenance and Care of Casters

Proper care extends the lifespan of casters and keeps environments safe. Regular inspections should include checking for cracks in wheels, loose fastenings, and irregular movement. Lubrication is critical for smooth operation—neglecting it leads to squeaks or increased push resistance. Locking mechanisms also require routine testing and debris clearing to prevent unexpected movement.

If casters exhibit signs of damage or excessive wear, prompt replacement is crucial to prevent workplace injuries and operational disruptions. Documenting a regular caster maintenance schedule as part of facility management protocols can go a long way to improving safety and efficiency.

Conclusion

Casters are indispensable solutions that support efficiency, safety, and flexibility across a spectrum of industries and public settings. Today’s advanced caster designs reflect years of innovation aimed at reducing physical strain, improving workflow, and minimizing injury risk. By understanding caster types, recognizing advancements, and ensuring regular care, businesses and individuals can maximize mobility while investing in long-lasting ergonomic solutions that make everyday tasks easier and environments safer.