Introduction

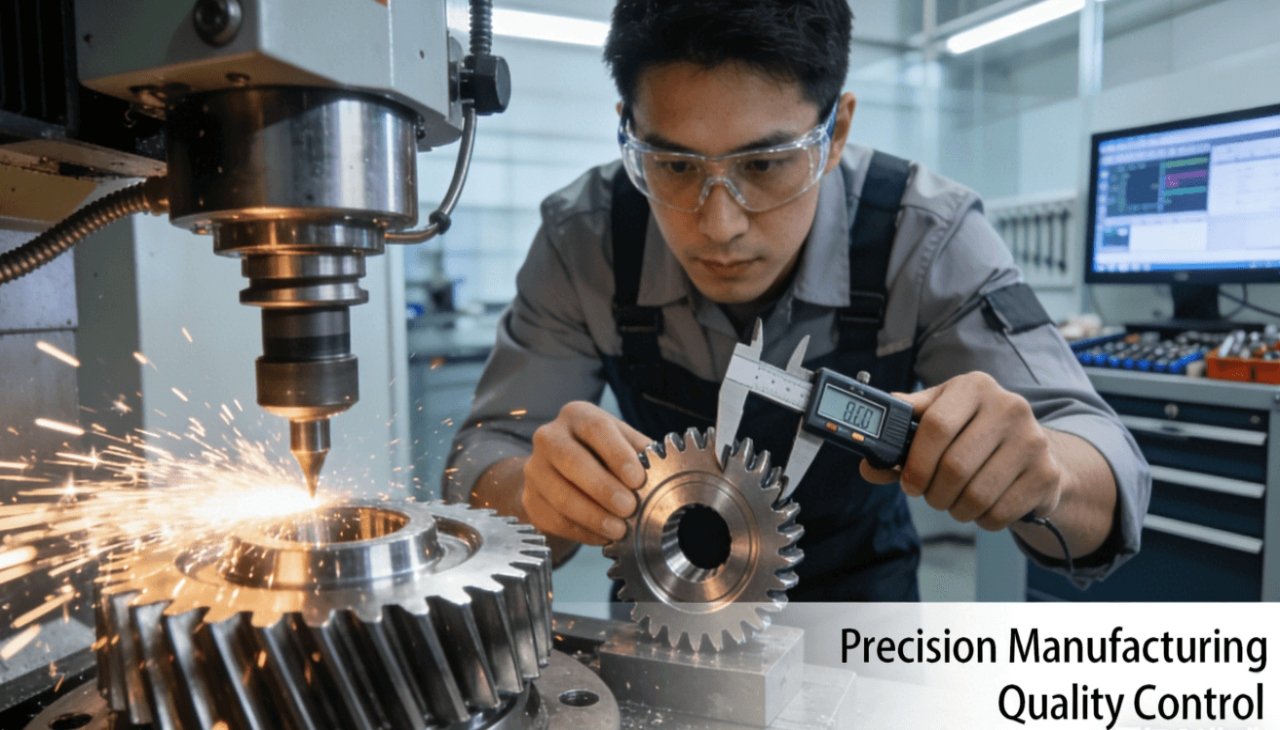

In the manufacturing sector, gear production frequently encounters significant challenges, including insufficient precision and extended production cycles. These issues directly lead to cost overruns and project delays. The fundamental problem lies in traditional gear manufacturing methods, which often rely on manual operations that introduce errors and lack the flexibility to adapt to custom demands efficiently.

This article introduces advanced CNC gear machining technology, which, when combined with rigorous precision manufacturing processes, enables high-precision and high-efficiency production. The following sections will provide an in-depth analysis of key technologies and practices to help optimize your production chain.

What is the Core Technology of Precision Gear Manufacturing?

The foundation of high-quality gear production rests on a synergy of disciplines, including materials science, CNC programming, and precision engineering. The core objective is to manufacture gears that meet exact design specifications with exceptional geometric accuracy and surface quality. In processes like spur gear machining, everything begins with sophisticated CNC programming. This digital blueprint translates gear parameters—such as tooth profile, module, and pressure angle—into machine-executable instructions, ensuring consistency across production runs

Material science is equally critical. Selecting the appropriate material, whether alloy steel, stainless steel, or engineering plastics, based on application requirements (e.g., high load, speed, or corrosion resistance) is paramount. Furthermore, predefined heat treatment processes are essential to optimize the material’s mechanical properties. The standards established by the American Gear Manufacturers Association (AGMA) provide a vital framework for quality and reliability, offering best practices for gear design, rating, and inspection. By integrating advanced CNC machining centers, rigid tooling, and in-process measurement systems, modern Industrial Technology controls the entire workflow from blank to finished gear, maintaining micron-level tolerances and establishing the basis for reliable Precision Manufacturing.

How to Improve Gear Accuracy through CNC Machining?

CNC Machining serves as the cornerstone for achieving micron-level accuracy in modern gear production. By eliminating the variability of manual operation, it plays a decisive role in the spur gear manufacturing process and the production of more complex gear types.

Multi-Axis Machining and Complex Tooth Form Generation

The limitations of traditional three-axis machines become apparent when machining gears with complex helices or modified profiles. Five-axis CNC Machining centers allow the cutting tool to approach the workpiece from multiple angles, enabling the complete machining of tooth slots, end faces, and chamfers in a single setup. This significantly reduces cumulative errors from re-fixturing and is particularly suited for the advanced manufacturing of high-performance custom parts.

Real-Time Monitoring and Process Control

Accuracy assurance extends beyond execution to include continuous monitoring. Advanced CNC systems integrate force sensors, vibration analysis, and thermal compensation modules to monitor the machining state in real-time.

- Automatic Tool Wear Compensation

Tool wear is a primary factor affecting tooth profile accuracy during high-speed cutting. Systems can be programmed with detection cycles to automatically invoke compensation routines when wear exceeds tolerance, ensuring dimensional consistency across production batches.

- In-Process Inspection Based on ISO Standards

On-machine probes can be integrated to measure critical dimensions during or immediately after machining. This data is compared against international benchmarks like the ISO 6336 calculation standard , facilitating closed-loop quality control and early deviation detection.

Digital Simulation and Error Prevention

Prior to physical cutting, comprehensive machining simulation and collision detection within CAM software allow for the optimization of tool paths and cutting parameters. This digital twin approach, a hallmark of advanced manufacturing, prevents errors like gouging or collisions at the source. As demonstrated in practical applications, such as the detailed overview of Spur Gear Manufacturing Services, this proactive strategy ensures efficiency from prototype to volume production.

What are the Common Problems in the Gear Manufacturing Process?

Even with advanced gear manufacturing techniques, several typical challenges can arise. Common issues include thermal distortion caused by cutting heat or improper heat treatment, leading to profile warping; material inhomogeneity or residual stress causing dimensional instability after machining; and inefficiencies or human errors from frequent changeovers in low-volume, high-mix custom parts production.

Traditional methods often struggle to address these problems effectively. For instance, relying on post-machining handwork to correct distortion is inefficient and compromises design integrity. The long lead times associated with dedicated tooling for custom parts highlight a lack of agility. Modern Industrial Technology offers systematic solutions. Controlled coolant systems, optimized cutting parameters to minimize heat input, and Finite Element Analysis (FEA) to predict and compensate for deformation are effective strategies. Sourcing materials from suppliers certified under standards like ISO 9001 ensures batch-to-batch consistency. Crucially, leveraging the flexibility of CNC production and digital management tools allows for rapid programming and setup changes, transforming potential pain points into standardized, optimized steps that balance quality, cost, and lead time.

How Can Advanced Manufacturing Technology Optimize Custom Parts Production?

Advanced Manufacturing technologies are fundamentally reshaping the production of custom parts, especially in CNC gear machining. These technologies enhance efficiency and provide unparalleled ability to meet complex and variable custom demands.

Additive Manufacturing and Hybrid Processing

For custom gear prototypes or small-batch components with extremely complex internal channels or lightweighting requirements, metal additive manufacturing (3D printing) offers unprecedented design freedom. When combined with subsequent CNC finishing (hybrid manufacturing), it ensures precision dimensions and superior surface finish on critical mating surfaces, enabling “design for manufacture” principles.

Automation and Flexible Manufacturing Cells

The integration of automated pallet systems, robotic part handling, and CNC machining centers creates Flexible Manufacturing Cells (FMCs).

- Enabling Rapid Changeover

With pre-set fixture libraries and automatic tool changers, the system can switch between different gear part numbers in minimal time, perfectly adapting to high-mix, low-volume custom parts orders.

- Enhancing Continuous Operation Efficiency

This enables 24/7 unmanned production, significantly shortening overall lead times while freeing operators for higher-value tasks like process monitoring and optimization.

Data-Driven Decision Making and Industry 4.0 Integration

Within the Industry 4.0 framework, every CNC gear machining process generates vast amounts of data. Integrating this data through a Manufacturing Execution System (MES) allows for transparent management of the entire workflow, from order entry and process design to production scheduling and quality traceability. This facilitates data-driven decisions, enabling dynamic production scheduling and predictive maintenance, ultimately maximizing efficiency and optimizing costs. Partnering with a service provider certified to stringent standards like IATF 16949, such as those offering custom gear manufacturing , ensures that this data-driven Advanced Manufacturing system is rigorously validated, providing reliable assurance for critical custom components.

What to Consider When Selecting Gear Machining Companies?

Selecting the right partner among gear machining companies is a critical step for project success. When evaluating suppliers, it is essential to look beyond quotation price and focus on several core competencies.

First, technical capability and equipment advancedness form the foundation. Assess whether the supplier possesses multi-axis CNC gear hobbers, precision grinding machines, Coordinate Measuring Machines (CMM), and gear-specific inspection equipment. This hardware determines their capability to handle high-precision, complex gears beyond a standard spur gear manufacturing process. Second, certifications and quality standards are a reliable indicator of a robust quality system. Beyond ISO 9001, industry-specific certifications like AS9100D for aerospace or IATF 16949 for automotive demonstrate a commitment to stringent, process-oriented quality control.

Furthermore, engineering support and customization experience are vital. A superior supplier should offer comprehensive engineering consultation covering material selection, tooth profile optimization, and heat treatment processes, rather than merely working from provided drawings. Inquiring about their experience with custom parts, especially in resolving technical challenges and meeting urgent delivery demands, is crucial. Finally, client testimonials and industry reputation provide real-world validation. Reviewing case studies and seeking client feedback can offer insights into delivery reliability and collaboration effectiveness. Choosing a company deeply committed to Precision Manufacturing, with comprehensive technical capabilities and proven management systems, is key to mitigating risk and ensuring project success.

Conclusion

In summary, modern precision gear machining has evolved from a skill-based craft to a discipline deeply integrated with CNC Machining, advanced materials, and digital workflows. By adopting high-standard practices—such as adhering to AGMA/ISO standards, implementing real-time monitoring, and leveraging data-driven decisions—manufacturers can significantly enhance gear accuracy and production efficiency, fundamentally avoiding cost overruns and project delays.

For those facing challenges with gear precision or demanding custom requirements, consulting with a professional engineering team is recommended. The JS Precision team offers end-to-end customized gear machining solutions, from technical assessment to volume delivery, ensuring optimal outcomes in quality, cost, and timeliness for your projects.

Author Biography

The author is a senior expert in the industrial manufacturing field, with over fifteen years of specialization in gear machining technology and precision manufacturing innovation. Having provided technical solutions and process optimization services for numerous globally recognized equipment manufacturers, the author is a core member of the JS Precision team, dedicated to translating cutting-edge Industrial Technology into reliable productivity for clients.

FAQs

Q1: What is the main advantage of spur gear machining?

A: Spur gear machining offers high transmission efficiency and a simple design, making it suitable for high-speed applications. CNC technology ensures precision up to ±0.01mm, reducing operational noise and wear.

Q2: How to evaluate the cost of gear manufacturing techniques?

A: Cost depends on material grade, required precision (e.g., ISO tolerance grade), and production volume. Referencing ISO standards for design optimization and employing advanced CNC and automation can reduce per-unit costs.

Q3: Is CNC gear machining suitable for small-batch production?

A: Yes, CNC technology is highly flexible, ideal for prototypes and small batches. Digital programming allows for quick changeovers without expensive dedicated tooling, maintaining quality and saving time.

Q4: What are common quality risks in gear machining?

A: Risks include tooth profile error, pitch deviation, and post-heat-treatment distortion. Selecting an ISO-certified supplier ensures process controls and inspection protocols to mitigate these risks.

Q5: How does advanced manufacturing improve delivery speed for custom parts?

A: Advanced manufacturing uses automation, simulation, and real-time data to shorten setup and processing times, often reducing the total production cycle for custom parts by over 30%.