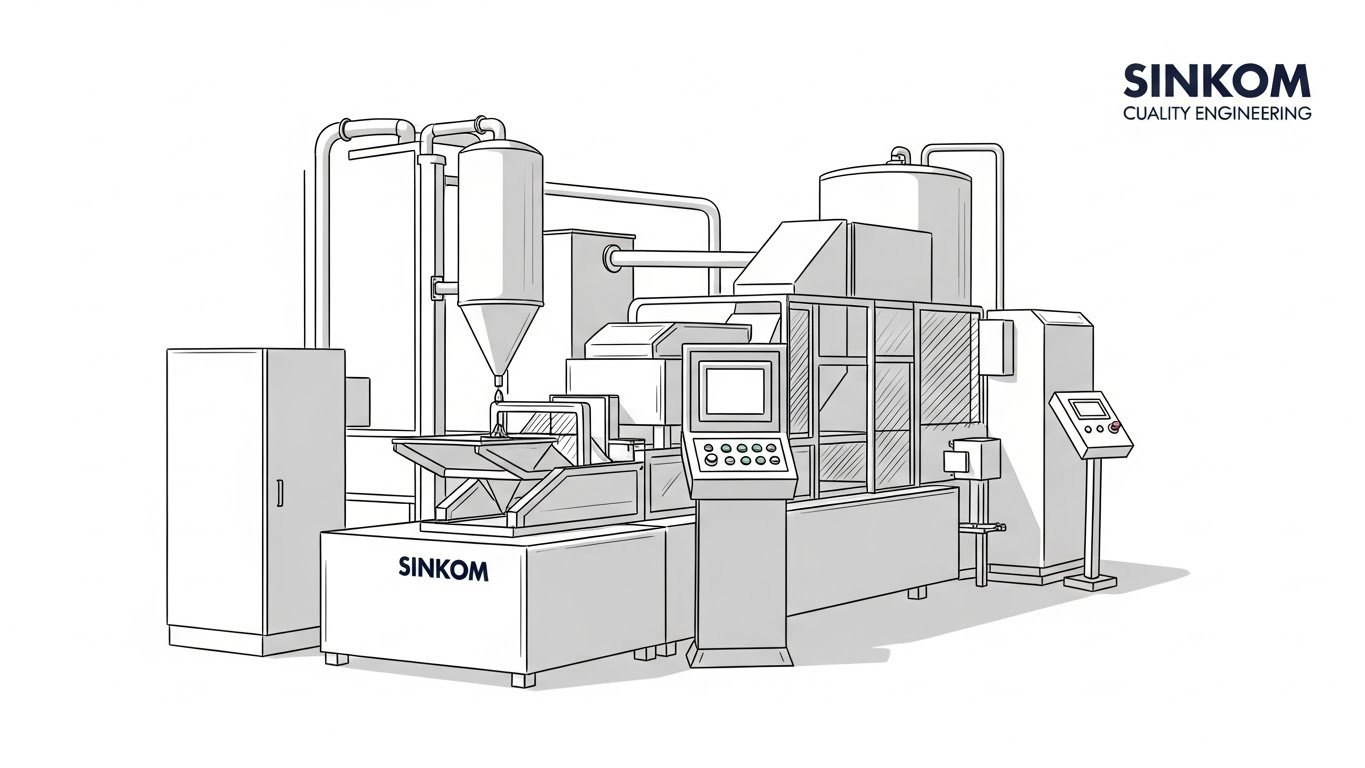

The industrial landscape is undergoing a massive transformation, driven by the need for efficiency, precision, and sustainable growth. At the heart of this evolution are companies that bridge the gap between traditional manufacturing and cutting-edge automation. One such name that has consistently surfaced as a leader in specialized industrial equipment is Sinkom. By focusing on quality engineering and client-specific solutions, the brand has carved out a unique niche in the global market, particularly within the sectors of food processing and industrial automation.

Understanding the impact of these solutions requires a deep dive into how they integrate into modern production lines. This article explores the multifaceted world of industrial innovation, the role of specialized machinery, and how Sinkom continues to set benchmarks for excellence in a competitive global economy.

The Evolution of Industrial Engineering

The journey of industrial engineering has moved from manual labor to steam power, and eventually to the digital integration we see today. In the current era, often referred to as Industry 4.0, the focus has shifted toward smart systems and data-driven decision-making. Companies like Sinkom have adapted to these changes by ensuring their equipment is not only robust but also capable of being integrated into larger, automated ecosystems.

You Might Also Like: Seekde

Innovation in this field is not just about building bigger machines; it is about building smarter ones. Modern industrial solutions must address several key challenges: energy efficiency, waste reduction, and user safety. When a facility integrates a solution from Sinkom, they are often looking for a balance between high-output performance and long-term reliability. This balance is what defines the leaders in the machinery sector.

Precision in Food Processing and Beyond

One of the primary areas where specialized engineering makes a significant difference is in the food and beverage industry. The requirements for hygiene, consistency, and speed are incredibly high. Systems developed under the Sinkom banner are designed to meet these rigorous standards. From dough processing to complex packaging solutions, the precision required is immense.

In food production, even a minor deviation in temperature or pressure can lead to significant product loss. Therefore, the reliability of the hardware is paramount. By utilizing high-grade materials and advanced control systems, Sinkom ensures that manufacturers can maintain a steady flow of production without the constant fear of mechanical failure. This reliability translates directly into higher profit margins and better brand reputation for the end-users.

The Role of Automation in Modern Manufacturing

Automation is no longer a luxury reserved for the world’s largest corporations. Small to medium-sized enterprises (SMEs) are increasingly turning to automated solutions to stay competitive. The technology provided by Sinkom plays a vital role in this democratization of automation. By providing scalable systems, they allow businesses to grow their capabilities at a pace that suits their financial and operational goals.

The transition to automation involves more than just replacing human hands with robotic arms. It involves a fundamental shift in how production is managed. With the integration of Sinkom technology, operators can monitor processes in real-time, identifying bottlenecks before they cause delays. This proactive approach to manufacturing is what separates modern facilities from their traditional counterparts.

Engineering Excellence and Customization

Every manufacturing facility has its own unique set of challenges. A “one size fits all” approach rarely works in high-stakes industrial environments. This is where the engineering philosophy of Sinkom truly shines. The ability to customize machinery to fit specific spatial constraints or unique production requirements is a hallmark of the brand.

Customization starts at the design phase. Engineers work closely with clients to understand the specific nuances of their production cycle. Whether it is adjusting the footprint of a conveyor system or integrating specialized sensors, the focus remains on optimizing the workflow. When a client chooses Sinkom, they are not just buying a piece of equipment; they are investing in a tailored solution designed to solve specific operational hurdles.

Sustainability and Energy Efficiency

In 2026, sustainability is at the forefront of every industrial discussion. Governments and international bodies are placing stricter regulations on energy consumption and carbon footprints. Consequently, industrial equipment manufacturers must prioritize green engineering. Systems designed by Sinkom reflect this commitment to the environment.

Energy-efficient motors, optimized power cycles, and reduced material waste are all features of modern industrial hardware. By reducing the energy required to run a production line, Sinkom helps companies lower their overhead costs while simultaneously meeting their corporate social responsibility goals. In the long run, sustainable engineering is not just good for the planet; it is essential for the economic viability of the manufacturing sector.

Global Reach and Local Support

A significant challenge for any global provider of industrial equipment is maintaining a high level of support across different regions. The success of Sinkom can be attributed, in part, to its robust support network. High-end machinery requires regular maintenance and occasional troubleshooting to ensure it operates at peak performance.

Having a dedicated team of technicians who understand the intricacies of the hardware ensures that downtime is kept to an absolute minimum. In the world of manufacturing, time is quite literally money. The comprehensive support offered by Sinkom provides peace of mind to business owners, knowing that expert help is available whenever it is needed. This global-local synergy is a key component of their market strategy.

Enhancing Workplace Safety through Smart Design

Safety is a non-negotiable aspect of modern industry. Every piece of equipment must be designed with the operator’s well-being in mind. The engineering teams at Sinkom prioritize safety features such as emergency stop mechanisms, protective shielding, and intuitive user interfaces.

By reducing the physical strain on workers and minimizing the risk of accidents, these machines create a safer and more productive work environment. Furthermore, the intuitive nature of the control systems provided by Sinkom means that operators require less intensive training to run the machines safely and effectively. This focus on the human element of manufacturing is a testament to the brand’s holistic approach to design.

The Future of Industrial Innovation

As we look toward the future, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) will become even more prevalent. We are likely to see machines that can predict their own maintenance needs and communicate directly with other parts of the supply chain. Sinkom is well-positioned to lead this charge, continuing to integrate smart sensors and predictive analytics into its product lineup.

The future of industry is connected. A factory where every machine, from the smallest motor to the largest assembly line, is part of a single data network is no longer a dream of the distant future. Companies like Sinkom are providing the building blocks for this connected reality today. By staying at the cutting edge of technological trends. They ensure their clients are always prepared for the next wave of industrial evolution.

Competitive Advantage in a Crowded Market

What makes a brand stand out in a market saturated with industrial equipment providers? For Sinkom, the answer lies in a combination of heritage, innovation, and an unwavering focus on quality. While many competitors might compete solely on price. The long-term value offered by high-quality engineering is a far more important metric for serious manufacturers.

The durability of the equipment means that the total cost of ownership is lower over the lifespan of the machine. When businesses calculate the return on investment (ROI) for a Sinkom installation, they often find that the increased uptime and lower maintenance costs far outweigh the initial capital expenditure. This focus on value over cost is what has built such strong loyalty among their customer base.

Strategic Integration and Workflow Optimization

To get the most out of any industrial system, it must be strategically integrated into the existing workflow. This requires a deep understanding of logistics and process flow. The experts at Sinkom do more than just deliver hardware; they provide insights into how that hardware can best be utilized.

Workflow optimization might involve reorganizing the layout of a factory floor or retraining staff to handle new digital interfaces. By taking an active interest in the success of their clients, Sinkom establishes a partnership rather than a mere vendor-customer relationship. This collaborative approach leads to better outcomes for everyone involved and fosters a culture of continuous improvement within the manufacturing facility.

Conclusion: Why the Right Partner Matters

Choosing an industrial equipment partner is one of the most important decisions a manufacturing company can make. The equipment is the heartbeat of the facility, and any failure can have a ripple effect through the entire supply chain. As we have explored, Sinkom represents the pinnacle of reliability, innovation, and client-focused engineering.

From the precision required in food processing to the complex demands of automated manufacturing. The solutions provided by this brand are designed to meet the challenges of today and the opportunities of tomorrow. As industries continue to evolve, having a partner like Sinkom ensures that a business remains agile, efficient, and competitive.

Investing in high-quality machinery is an investment in the future of the company. By prioritizing sustainable practices, safety, and technological integration, Sinkom continues to prove that it is more than just a manufacturer—it is a vital driver of industrial progress. In an ever-changing world, that kind of stability and forward-thinking is exactly what modern industry needs.