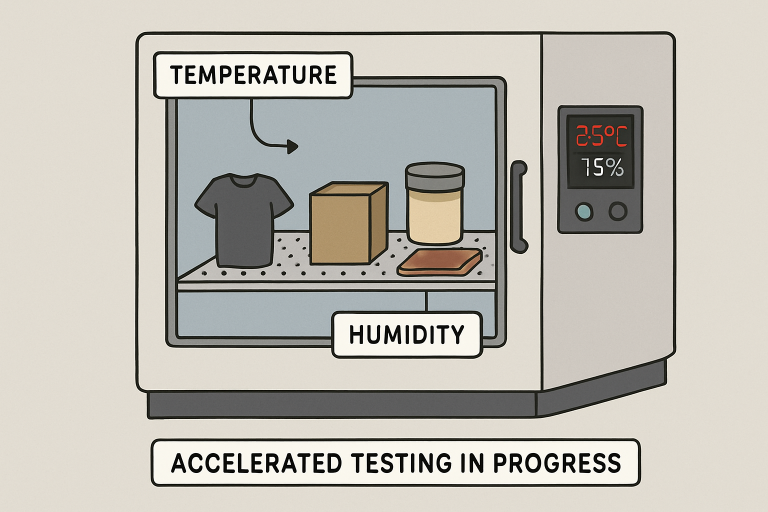

In delivering products to market, companies face the challenge of ensuring reliability, durability, and safety. Accelerated environmental testing methods have become vital in meeting these demands by replicating years of natural wear and exposure within a short timeframe. By adopting processes that rapidly simulate harsh conditions, companies gain insights into product weaknesses long before they result in costly failures. One essential piece of equipment for these tests is an environmental chamber, which can recreate various stress factors—such as temperature extremes, humidity, or UV exposure—tailored to specific industry needs. Engineers use environmental chambers to identify vulnerabilities early, ensuring compliance and meeting durability expectations. This proactive approach helps manufacturers avoid setbacks, reduce warranty claims, strengthen brand reputation, and support approvals. As industries like automotive and medical devices elevate standards, accelerated testing offers a competitive edge by revealing flaws and improving product quality with less waste.

Understanding Accelerated Environmental Testing

Accelerated environmental testing involves intentionally subjecting products and materials to intensified versions of the conditions they’ll face in actual use—such as extreme heat, cold, moisture, sunlight, vibration, or chemical exposure. By condensing timelines from years to weeks or months, these tests provide critical feedback much earlier in the development cycle. Manufacturers can then validate claims of long service life or robust performance, which is especially important in safety-critical or highly regulated sectors. These evaluations also help pinpoint failure modes that may not appear under standard testing conditions. The insights gained support more efficient design iterations and better risk mitigation strategies. Ultimately, accelerated environmental testing ensures that products reach consumers with proven reliability and confidence.

Advantages of Accelerated Testing

- Time Efficiency: Traditional product lifecycle tests can run for years, while accelerated methods accomplish meaningful simulation within mere weeks or months. This rapid cycle means products reach the market faster without compromising on quality assessments.

- Cost Reduction: Early detection of design or material issues helps avoid costly recalls, warranty claims, or late-stage redesigns, resulting in significant savings in R&D and manufacturing.

- Improved Reliability: Proactive identification and remediation of vulnerabilities lead to more robust end products, reducing the likelihood of in-field failures and enhancing trust with customers and end-users.

- Regulatory Compliance: Accelerated testing provides proof that products meet the required endurance standards, streamlining the path to market entry and ongoing certification. Regulatory bodies may often prefer or require data obtained from recognized accelerated testing protocols, particularly in fields such as electronics or healthcare devices.

Common Accelerated Testing Techniques

- Highly Accelerated Life Testing (HALT): In HALT, products are exposed to progressively harsher conditions until they fail, revealing design weaknesses and their breaking points. This approach is crucial in electronics, telecommunications, and medical equipment.

- Accelerated Weathering Testing: Simulating environmental conditions such as UV radiation, rain, temperature shifts, and humidity, accelerated weathering testing provides valuable insights into a material’s resistance to fading, cracking, or degradation. Industries such as automotive, construction, and packaging rely on this data to ensure the long-term integrity of their products.

- Thermal Cycling: Subjecting products to repeated temperature extremes assesses their resilience to expansion, contraction, and eventual fatigue. Thermal cycling is particularly pivotal in aerospace, military equipment, and electronics, where temperature changes can be frequent and severe.

Challenges in Accelerated Testing

- Correlation with Real-World Conditions: Designing tests that truly mimic operational environments is challenging. If stressors are applied too forcefully, they may trigger failure modes not seen in actual service, leading to over-engineering or misinformed decisions.

- Overstressing Products: Pushing products beyond their expected operational limits can sometimes yield unrealistic results. Striking the right balance is essential for meaningful conclusions.

- Cost of Equipment: Advanced testing facilities, such as programmable environmental chambers, require significant investment and maintenance. Nevertheless, organizations often find that the long-term savings and protections outweigh the initial expenses.

Innovations in Accelerated Testing

- Machine Learning Integration: Modern approaches increasingly combine AI and machine learning models to interpret vast data sets from accelerated testing. These tools can help forecast device lifespan with greater accuracy and even suggest optimized testing parameters.

- Advanced Simulation Models: Today’s accelerated testing can combine physical and chemical simulations to predict better the nuanced ways materials degrade under prolonged exposure to stressors. This integration enables industries to design more resilient and longer-lasting products, thereby contributing to both sustainability and profitability.

Implementing Accelerated Testing in Product Development

Define Testing Objectives: Be specific about what you need to learn. Is the key concern corrosion, fatigue, electronics reliability, or material breakdown?

Select Appropriate Methods: Match testing environments to typical product use and likely stress encounters for best relevance.

Analyze Results Thoroughly: Patterns in the data often highlight not only apparent design failures but also more subtle material or component weaknesses that may emerge over time, particularly during years of service.

Iterate as Needed: Use insights to refine products. More than one testing cycle may be required for continuous improvement and truly robust design.

Conclusion

Accelerated environmental testing methods are crucial for companies seeking to deliver products that meet stringent standards for performance and durability. Through careful planning, targeted testing, and diligent application of results, manufacturers reduce their time to market, foster innovation, and build consumer trust. As industries adopt new technologies such as machine learning and advanced simulations, the precision and predictive power of these tests will continue to grow, ushering in an era of even more reliable and sustainable products worldwide.