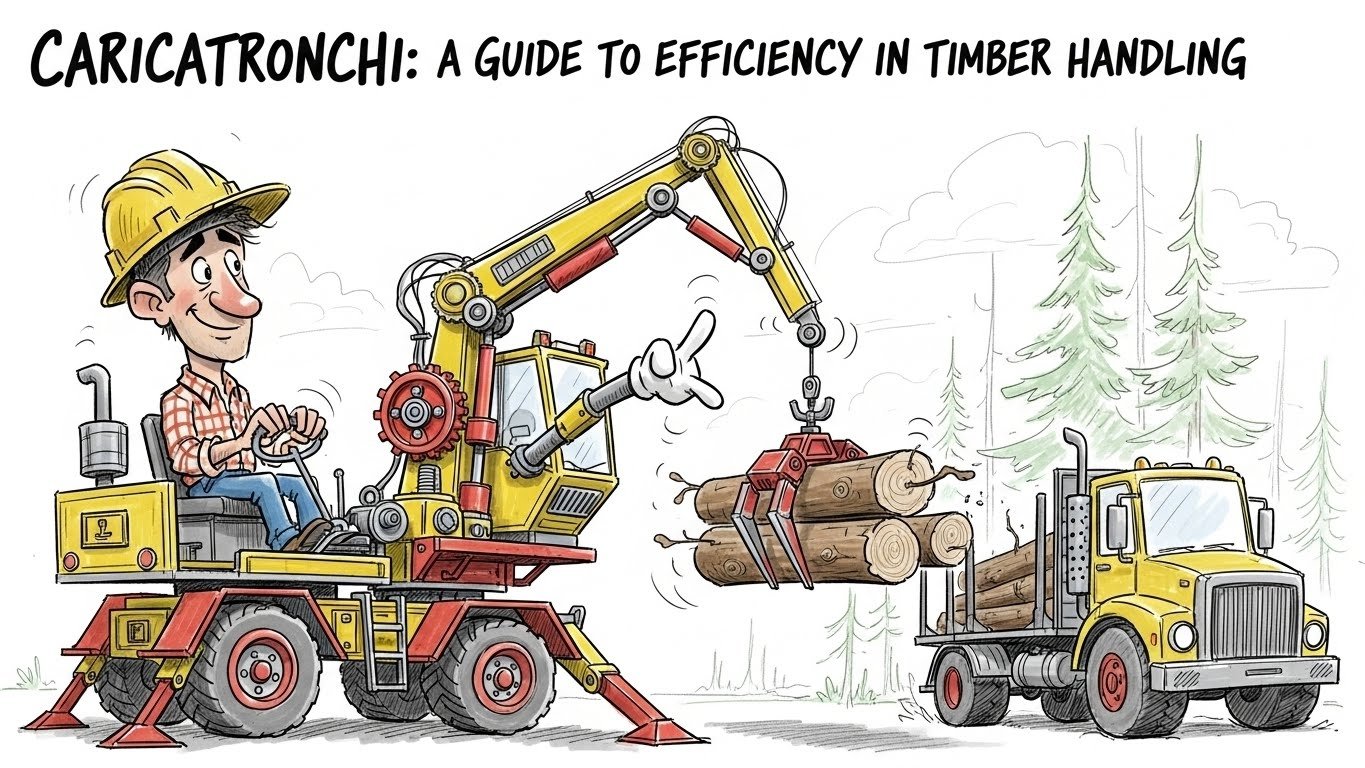

The modern forestry industry has undergone a radical transformation over the last few decades, moving from labor-intensive manual methods to highly mechanized processes. At the heart of this evolution is the caricatronchi, an indispensable tool for the movement, loading, and unloading of timber. This machinery is not just a logistical support; it is the vital link that ensures the fluidity of the supply chain, from the deep forest to the sawmill.

In this comprehensive article, we will explore the characteristics, types, and best practices for using this essential forestry device, providing a complete overview for professionals and companies in the sector.

Understanding the Caricatronchi and Its Core Function

Fundamentally, a caricatronchi is a specialized piece of operating machinery equipped with a hydraulic arm and a specific grapple, designed to grip and lift logs of various sizes and weights. Its primary function is to optimize loading times on transport vehicles or to organize timber stacks in storage yards.

You Might Also Like: Pechiparai Dam

Without the aid of such advanced technology, the timber sector would suffer from insurmountable bottlenecks. The ability to handle large volumes of raw material in a short time allows companies to respond promptly to market demand while maintaining high safety standards for operators, who no longer need to handle heavy loads in often precarious conditions.

Technical Evolution and Types of Machinery

The market offers various configurations of this equipment, each suited to specific operational needs. The choice of the correct model depends on the working environment, the volume of timber to be treated, and the required mobility.

Truck-Mounted Models

This is perhaps the most common variant for long-distance transport. The caricatronchi is mounted directly on the truck chassis or trailer. This configuration allows the driver to load their vehicle independently in the woods and unload it once they reach their destination, eliminating the need for a second lifting medium on site. These units are designed to be lightweight yet strong, ensuring they do not consume too much of the truck’s payload capacity.

Stationary Forestry Cranes

In sawmills or biomass centers, fixed installations are often preferred. These machines are designed for intensive and continuous use, constantly feeding the cutting lines or shredders. The stability guaranteed by ground fixing allows for higher flow rates and longer booms compared to mobile models. They often run on electric power, reducing operational costs and emissions in a fixed industrial environment.

Self-Propelled and Tracked Loaders

For operations that require frequent movements within a yard or on impervious terrain, the self-propelled caricatronchi represents the ideal solution. Equipped with rubber tires or tracks, these vehicles offer 360-degree visibility thanks to raised cabins that allow the operator to dominate the work area, ensuring millimeter precision even in the most difficult environmental conditions.

Fundamental Components and Mechanics

To understand the efficiency of a caricatronchi, it is necessary to analyze its main components. Each part is designed to withstand extreme stress and uninterrupted work cycles.

- The Hydraulic Arm: Made of high-strength steel, it can be a fixed arm or telescopic to increase the reach. The geometry of the arm is calculated to provide maximum lifting force at various extensions.

- The Grapple (Pinza): This is the gripping organ. There are various types: from crossed-finger grapples for single logs to wide-fork grapples for brushwood or biomass.

- The Hydraulic System: The true muscle of the machine. High-pressure pumps and sensitive distributors allow fluid and simultaneous movements, reducing mechanical wear and fuel consumption.

- The Control Cabin: In modern models, the cabin is a hub of ergonomics and technology, often equipped with air conditioning, ergonomic seats, and multi-function joysticks that reduce operator fatigue.

The integration of these elements defines the lifting capacity and the operational speed of a professional caricatronchi.

The Importance of Hydraulic Power and Precision

Hydraulics is the factor that determines the difference between a job well done and a waste of time. A high-quality caricatronchi must have a hydraulic circuit capable of handling heavy loads without overheating. The use of high-quality synthetic oils and high-efficiency filters ensures that the system remains reactive even after hours of use under the summer sun or in the winter frost.

Advanced valves and safety blocks are equally crucial: they prevent the accidental fall of the load in the event of a hose rupture, protecting the lives of those working near the machinery. Furthermore, the precision of the hydraulic “flow sharing” systems allows the operator to perform multiple movements (rotation, extension, and gripping) at the same time without losing power.

Operational Safety and International Regulations

Using a caricatronchi involves intrinsic risks associated with the movement of suspended loads. Safety must always be the top priority for every forestry operator.

Personnel Training

Maneuvering a forestry crane requires specific training. It is not just about knowing how to move the levers, but about understanding the center of gravity of the loads and the structural limits of the machine. In many jurisdictions, it is mandatory to hold specific certifications that attest to the operator’s competence.

Maintenance and Daily Inspections

A daily check is essential for the longevity of the caricatronchi. Before starting the shift, the operator must verify the integrity of the hydraulic hoses, the absence of cracks in the arm’s welds, and the correct greasing of the pins. A well-maintained machine is not only safer but also significantly more productive.

Safety Note: Never exceed the lifting capacity indicated by the manufacturer’s load chart. The risk of the vehicle tipping over or structural failure increases exponentially beyond the nominal limit.

Criteria for Choosing the Right Equipment

Purchasing such machinery is a significant investment. To maximize the return on investment (ROI), several technical and economic factors must be evaluated.

- Lifting Capacity: Evaluate the average and maximum weight of the logs you will move. An undersized caricatronchi will always work under stress, reducing its useful life.

- Maximum Reach: How far does the arm need to reach? If you work in large yards, a long boom will reduce the need to continuously move the vehicle.

- Machine Weight: If you install the loader on a truck, you must consider how much weight it adds to the vehicle. Modern high-tensile steels allow for lighter but stronger structures.

- After-Sales Service: Availability of spare parts and specialized technical assistance is vital. A machine downtime of a few days can cause significant economic losses in the peak of the season.

Maximizing Productivity in the Field

To get the most out of a caricatronchi, the operator must adopt efficient working techniques. This includes positioning the vehicle on level, stable ground and planning the movements to minimize the rotation angle. Every second saved in a loading cycle translates into more tons handled per day.

The use of digital monitoring systems is also becoming common. Some modern units are equipped with weighing systems integrated into the grapple, allowing the operator to know the exact weight of the load in real-time. This prevents the overloading of trucks and ensures compliance with road transport regulations.

Environmental Impact and Sustainability

The modern forestry industry is increasingly focused on sustainability. Manufacturers of the caricatronchi are responding by developing more efficient engines that comply with the latest emission standards (such as Stage V or Tier 4 Final).

Additionally, the transition toward bio-degradable hydraulic oils is gaining traction. In the event of a leak in the forest, these oils break down naturally without contaminating the soil or groundwater, preserving the delicate ecosystem in which these machines operate.

The Future: Automation and Remote Control

The future of the caricatronchi is leaning toward increased automation. We are already seeing the introduction of “smart” cranes that can partially automate repetitive movements, such as returning the grapple to a predefined “home” position.

Remote control technology is also advancing. In hazardous environments or specifically steep terrains, an operator can control the caricatronchi from a safe distance using a remote control station equipped with cameras and VR sensors. This not only increases safety but also allows for a more comfortable working environment, potentially attracting a new generation of workers to the forestry sector.

Conclusion

The caricatronchi remains a pillar of the timber industry. Its ability to bridge the gap between the raw forest environment and the industrial processing plant is unmatched. By choosing the right model, ensuring rigorous maintenance, and prioritizing operator training, companies can significantly increase their operational efficiency and safety.

As technology continues to advance, we can expect these machines to become even more precise, powerful, and environmentally friendly. Whether it is a truck-mounted unit for high-speed logistics or a heavy-duty stationary crane for a sawmill, the caricatronchi is the engine that keeps the wood industry moving forward.

Would you like me to help you create a specific maintenance checklist or a comparison table for different models of this machinery?